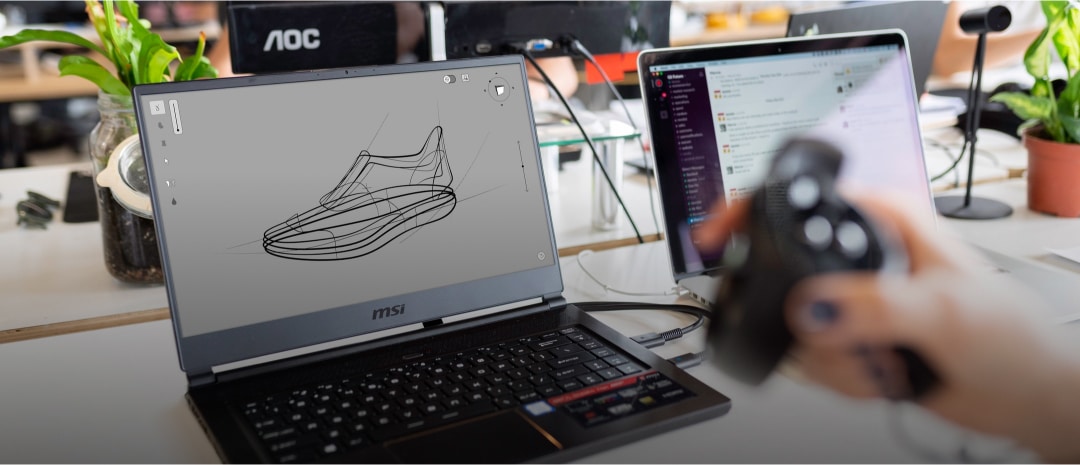

No longer simply a gimmick used for novelty games like Pokémon Go, augmented reality has evolved into a solid technology that be used effectively for both B2B and B2C purposes. The development of an augmented reality app can provide you with a significant competitive advantage – and wow your partners and clients.

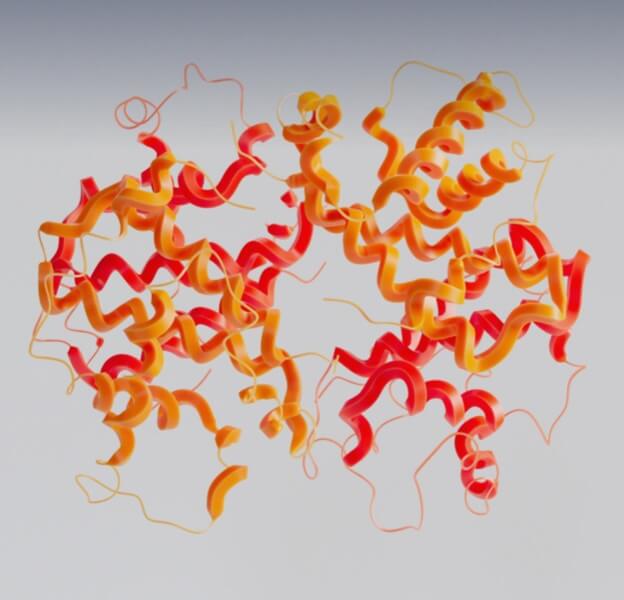

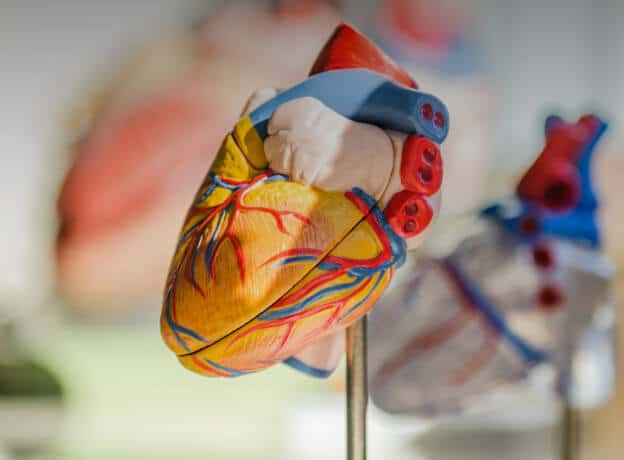

- Photorealistic 3D products and models

- Provides a memorable wow effect

- Direct impact on sales and customer engagement

- Competitive edge